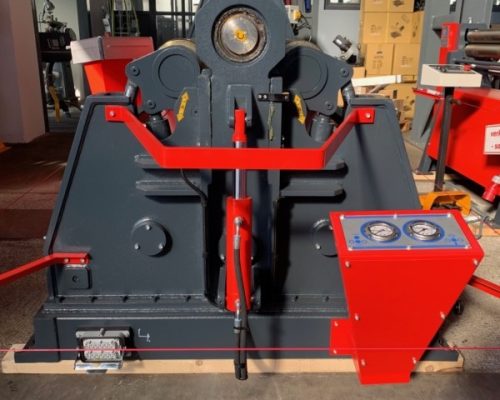

Accessories / equipment:

– Conical bending device

– induction hardened rolls

– digital display for side rollers

– Machine made of steel construction

– Separate control panel

– two speeds

– all rollers on ball bearings

– Folding and support bearing from the top roller is actuated from the control panel.

When the folding bearing is opened, the roller moves automatically upwards.

– Conical adjustment of the rollers via control panel

– Central rollers are via hydraulic motor and rotary reduction gear

driven. (Top and bottom rollers)

– Calibration

| sheet width | 2100 | mm |

| plate thickness | 13 | mm |

| pre-bending | 10 | mm |

| upper roll diameter | 230 | mm |

| lower roll diameter | 210 | mm |

| side roll diameter | 190 | mm |

| total power requirement | 7,5 | kW |

| weight of the machine ca. | 4.750 | kg |

| dimensions of the machine ca. | 4150x1400x1300 | mm |

4040214

Steuerung: NC

Metal Processing, Sheet metal working / shaeres / bending, Plate Bending Machine – 4 Rolls